3D Machine Control Summary

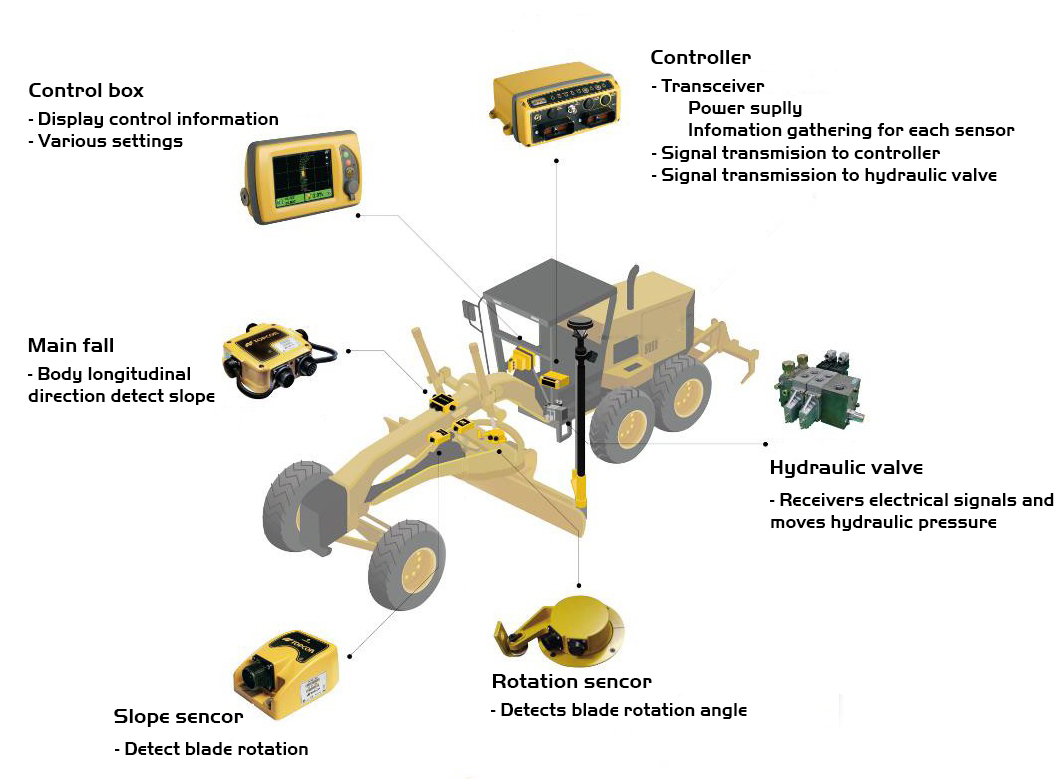

Machine Control:

- 3D grader using the technology that controls automatically operating device

- Use positioning information from the total station and 3D design data

Machine Guidance:

- A system that uses the same principle but gives instructions on what kind of work device should be moved, not automatically controlled.

- Even if there is no work index, the operator of the heavy equipment can finish the construction object into an appropriate shape.

3DMC = 3 DIMENSION MACHINE CONTROL

It can be used with both GNSS and total station positioning methods, but there are differences in the features.

| Item | GNSS | Total Station |

|---|---|---|

| Control area | Diameter 2km | Diameter 300m |

| Accuracy | Vertical direction ±40mm | Vertical direction ±10mm |

| No. of controllable units | 1 to n (In control area) | 1 to 1 |

| Weather | It does not affect | NG when raining or snowing. Reduced accuracy in dense fog and dust |

| Location | Cannot be used in places where the sky is blocked |

Machine blade of grader moves automatically according to the design shape

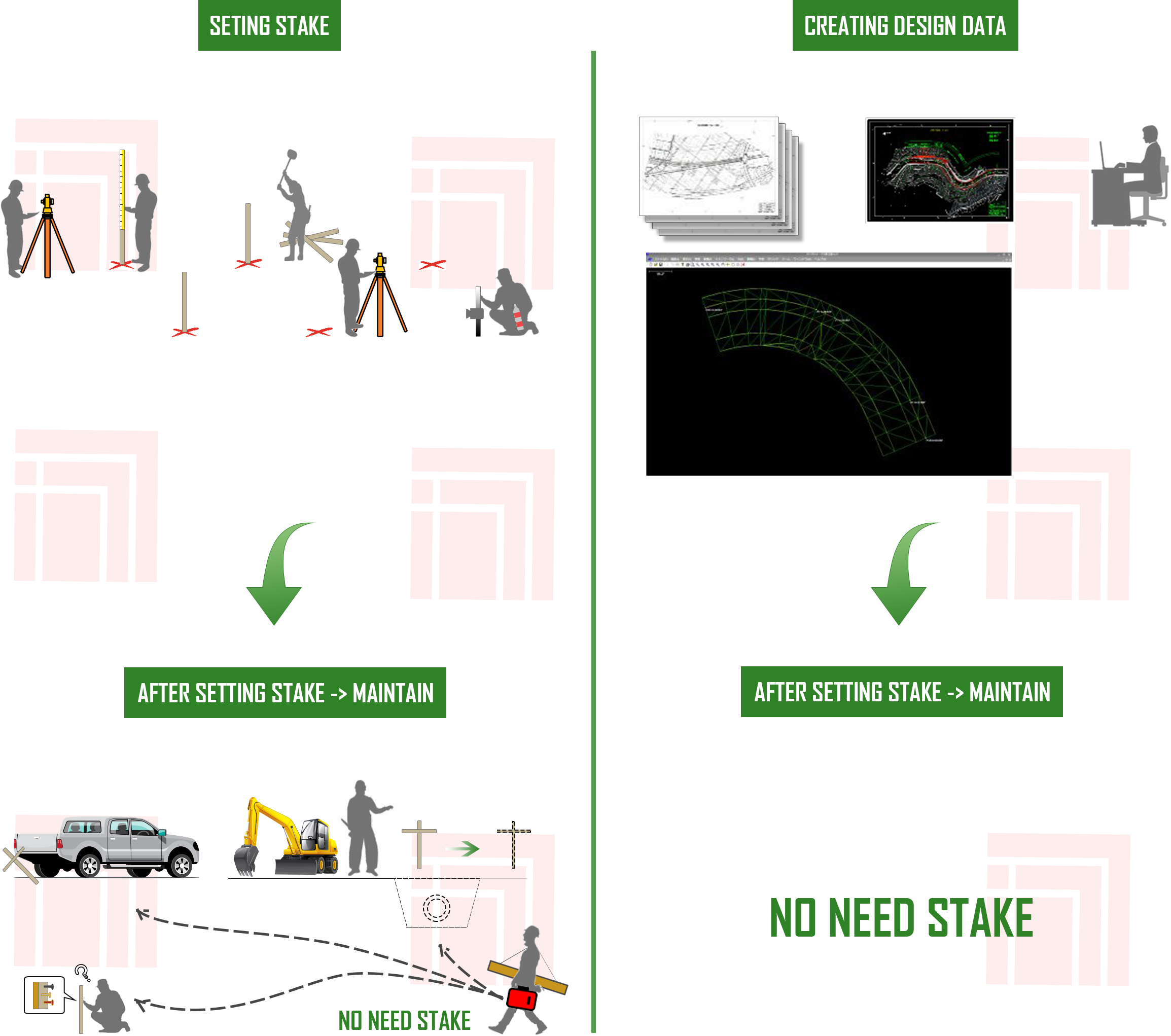

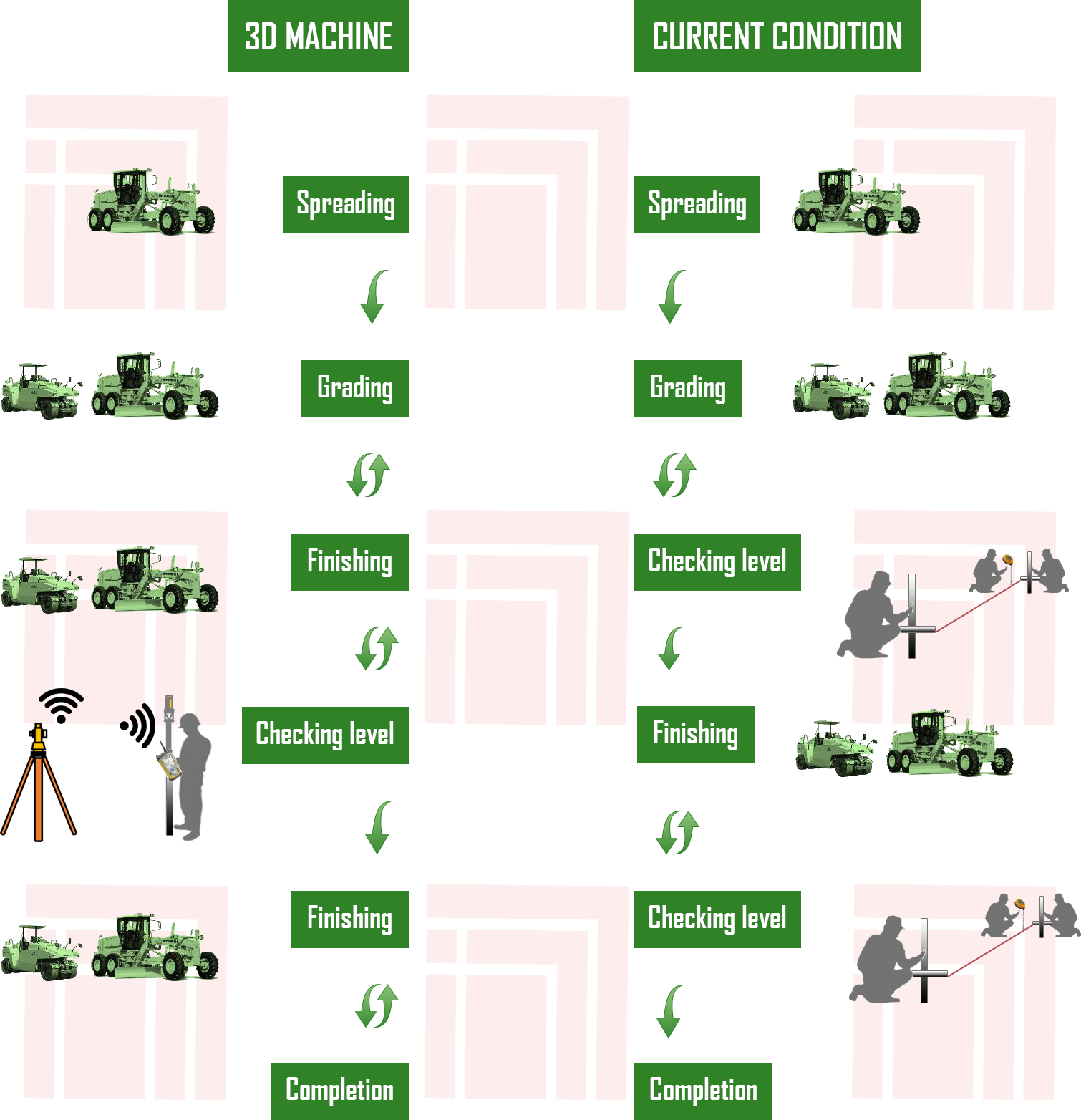

BENEFIT OF USING 3D GRADER

- Decrease the stakes for elevation and alignment

- Decrease manpower and cost for setting the stakes

- Decrease the checking elevation

- Reduced inspection work around heavy machinery → Improved safety

- Schedule shortens

- Continuous grading is possible

Post a Comment